Six Signs a Treadmill Motor Is Going Bad

The best time to fix a failing treadmill motor is now. Waiting increases the likelihood of having to replace the motor and/or sustaining damage to other treadmill components. Since the motor is among the most expensive parts to replace, being aware of the signs of trouble can save you a lot of time and stress in the future.

Keeping your treadmill motor and enclosure clean is the most effective measure you can take to prevent a host of issues that can cause failure. Photo by: Oleksandr Kosheliev / TreadmilReviews.net

Overheating

If you begin to notice your treadmill belt and/or deck are hot to the touch, there’s a chance your motor is overheating. In the short term, this can be inconvenient when your belt slows down under your body weight. More permanent consequences include a variety of mechanical issues including complete motor failure requiring replacement. Overheating is a common sign of dust buildup and/or lack of belt lubrication.

Excessive Noise

There are a number of reasons your treadmill may be making more noise than usual. One possibility is accumulation of dirt and debris in and around the treadmill motor. When this is the case, it’s common to experience concurrent issues like overheating and inefficient overall treadmill performance.

Belt Isn’t Running

Sometimes, a belt can get jammed, in which case all you need to do is remove whatever debris that’s causing the problem. A belt that’s not moving can also be a sign there’s a power interference preventing the motor from running. In the worst case, the motor may have quit working completely and needs to be replaced.

Hot/Burning Smell

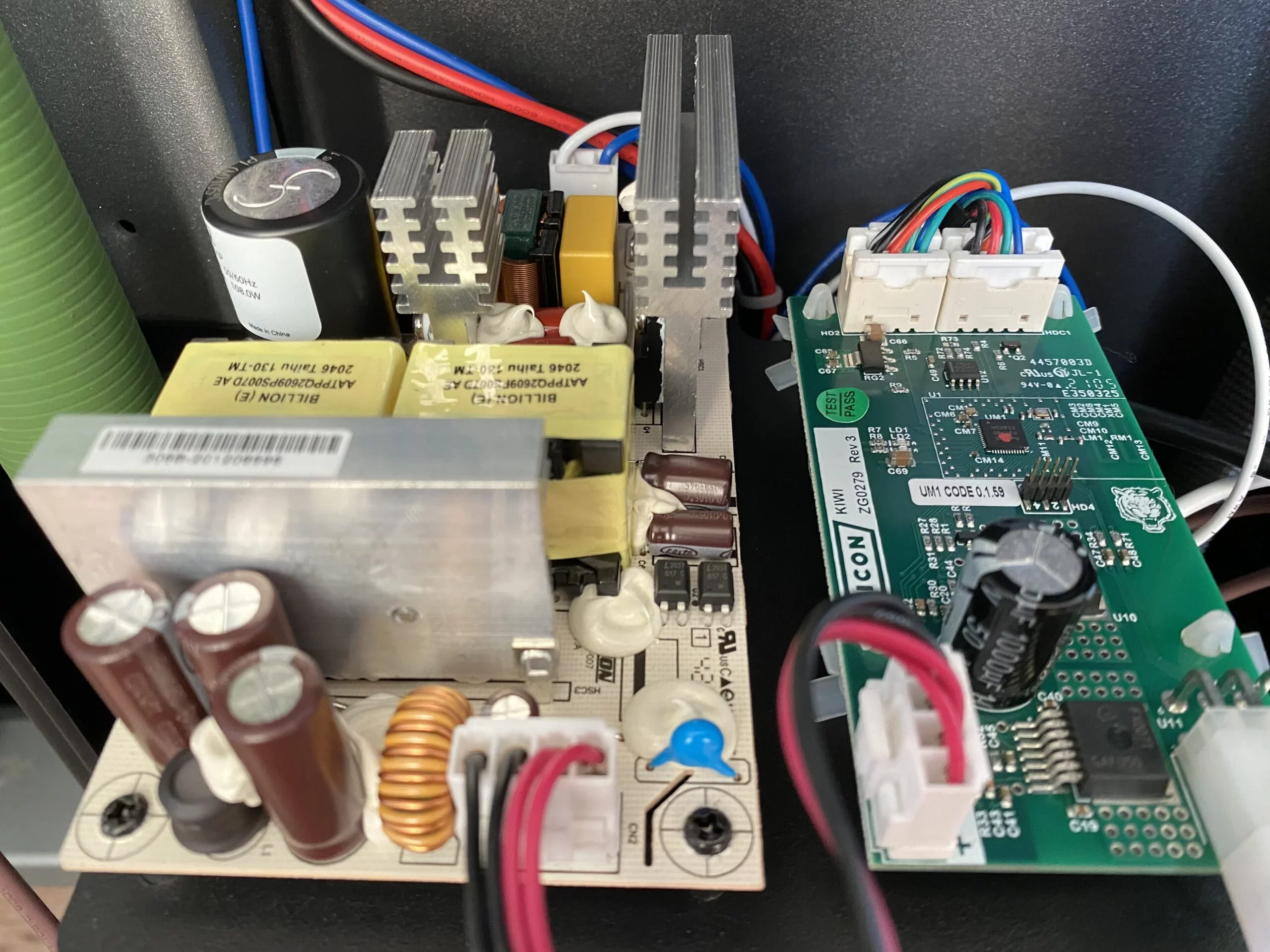

This fully-functioning control board is free of telltale burn marks that indicate short circuits and other power issues. Photo by: Jessica Jones / TreadmillReviews.net

Although there are different reasons you may be experiencing a hot/burning smell when using your treadmill, one common cause is a circuitry issue. Short circuits in the motor and its wiring require immediate attention to avoid serious motor issues.

Sparks

When the motor brushes wear out, it’s possible for the treadmill to produce sparks while in use. If this happens, turn off the machine immediately, and inspect the brushes.

Dysfunction Speed and/or Incline Controls

If your machine’s incline and/or speed controls aren’t functioning properly or have stopped working completely, this can be an indicator of either a motor or belt issue. For potential motor issues, let’s take a look at some testing methods.

How to Test for a Bad Motor

Suspecting something’s wrong with your motor should lead to action. If you’re unsure of your ability to run mechanical diagnostics, it could be a good idea to call a qualified technician to take a look. Before attempting any of the following tests, always unplug the treadmill, and remove the safety key. At the very least, take time to educate yourself on the ins and outs of treadmill motor mechanics and variables.

Basic Tests

Shaft and Bearing Inspection

As one of the most commonly worn parts of a treadmill motor, it can be helpful to know how to check the bearings. Issues like inefficiency in treadmill performance can be an indicator that an inspection is warranted, and it’s easier than you might think. Just push and pull the motor shaft to see if there’s friction between the shaft and bearings. Excessive friction indicates the need to replace bearings.

Check the Treadmill Fan

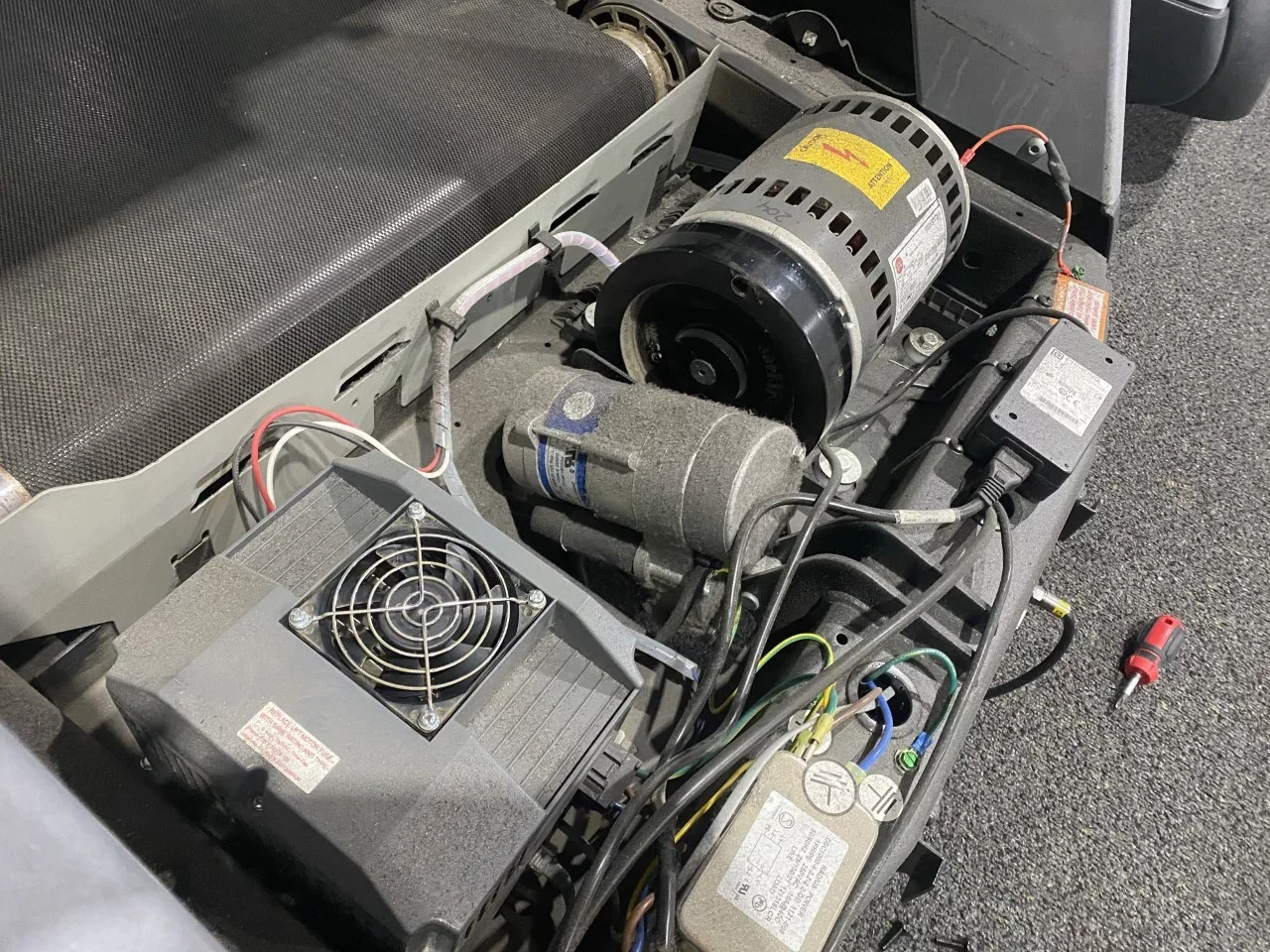

The fan inside this motor enclosure has pulled in a significant amount of dirt and debris, putting the motor at risk of numerous issues. Photo by: Jessica Jones / TreadmillReviews.net

When the motor fan isn’t working properly, overheating becomes a concern. Because of the airflow produced when the fan is running, dust and debris buildup poses a concern. When you perform your monthly vacuuming of the motor enclosure, make sure you sweep your vacuum across the fan. You can also take this opportunity to make sure your fan rotates without any obstruction.

More Advanced Testing

Multimeter Tests

If you plan to do your own treadmill motor repairs and don’t own a multimeter, you’ll need to get one as they can help diagnose a number of motor problems through measuring different electrical components like voltage, resistance, and current. These tests are more advanced. If you’re not confident in your ability to use a multimeter, call a qualified technician or the manufacturer for next steps.

- To check for general power supply issues, ensure the voltage is within proper range. While in use, a typical treadmill readout should be between 3.2V to 6.5V.

- Motor winding wear and tear can be tested by setting your multimeter to Ohms, disconnecting the two power supply wires, and testing each. A reading of zero indicates a bad cable, and infinite readings of each cable indicates an issue with the motor.

- Broken wires are indicated when tested cables produce readouts over 2 Ohms.

- Cable shorts are indicated with multimeter readouts of 0 Ohms.

The Bottom Line

If you determine your treadmill motor is bad, it’s important to fix it as quickly as possible. The sooner you can get it taken care of, the longer you may be able to maintain the various mechanics that make up your treadmill.

Other Treadmill Reviews:

- Test HomePage

- NordicTrack Commercial X14i

- Echelon Stride

- NordicTrack C 590 Pro

- NordicTrack T 7.5 S - Pros & Cons (2024)

- Sole TD80 Treadmill Desk

- NordicTrack Commercial X11i

- NordicTrack T 8.5 S - Pros & Cons (2024)

- Horizon Elite T5

- Exerpeutic TF1000

- NordicTrack T 6.5 S - Pros & Cons (2024)

- ProForm Sport 5.0

- ProForm Premier 900

- ProForm ZT6

- NordicTrack FreeStride Trainer FS5i (Discontinued)

- Bowflex Max Trainer M5

- BowFlex TreadClimber TC100

- ProForm Power 795

- ProForm Sport 7.0

- NordicTrack Incline Trainer X15i

- NordicTrack C 1650 Treadmill

- Horizon Elite T9

- Official Boston Marathon Treadmill 4.0

- NordicTrack Treadmill Desk

- NordicTrack C 1630 Pro

- NordicTrack C 970 PRO

- Bowflex TC20 TreadClimber